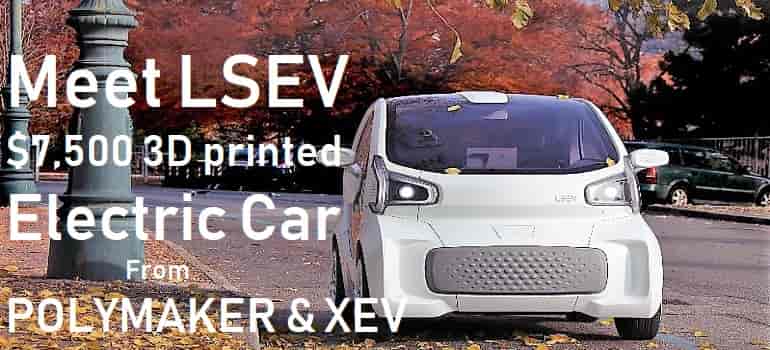

XEV and Polymaker has partnered to create the first mass-producible 3D printed electric car. The $7,500 electric car named as LSEV took just three days to make . Except chassis, seats and glass all other components in LSEV were 3D printed.

Polymaker developed dozens of kinds of engineering plastics for XEV to meet their needs of practical applications. As a result, 3 crucial achievements have been accomplished.

- XEV has decreased the plastic parts and number of components in a car from more than 2,000 to 57, and the finished LSEV weighs only 450 kilograms, much lower than similar sized vehicles usually weighing between 1 and 1.2 metric tons.

- Apart from the chassis, seats and glass, all the visible parts of the car are made by Polymaker materials through 3D printing. This switch of production leads to more than 70 percent reduction of the investment cost in comparison with a traditional production system.

- Conventionally the R&D process of a car model takes about 3-5 years, but it only takes XEV 3-12 months to finish a new design.

Polymaker have also come up with solutions to help with surface treatments and color. These solutions are enormously helpful in customized production and 3D printing volume production. (Read Meet LSEV $7,500 3D printed electric car from POLYMAKER & XEV)

XEV has already received 7000 orders from Europe even before mass production commences. 5000 orders come from Poste Italiane. And the other 2000 orders come from ARVAL, a vehicle leasing company fully owned by BNP Paribas. XEV plans to start production in the second quarter of 2019.